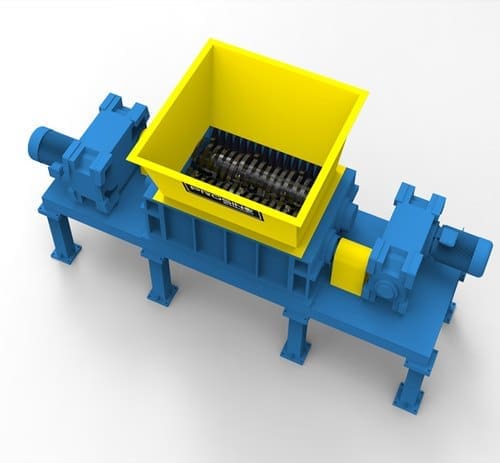

Twin Shaft Shredder

The twin shaft shredders are versatile shredders designed for shredding many types of bulky material in the primary stage. The shredders are extremely rugged and have a strong support structure to withstand all loads. Shredders are available in a wide range of electrical and hydraulic drive configuration. Feed conveyors and output conveyors can be provided. The housing is solid construction, bolted together.

The bearing unit is separate and properly sealed to avoid damage from liquid and solid material, thereby increasing its life. The shredders have low speed, high torque, low noise, low dust and low maintenance. In case the shredder is overloaded and foreign objects are in the cutting unit, the rotor stops and moves backward after which it returns to its original direction (auto reverse). The blades are made from special hardened steel and are easily replaceable. The design of the blades varies according to the material being shredded. Higher capacity shredders are provided with two gear box system ensuring constant torque on both shafts. The shafts are counter rotating and hexagonal in design ensuring excellent griping of the blades. Electricals and gear boxes are conform to applicable CE regulation and are CE Marked. The twin shaft shredders are used for shredding of Medical Waste, Municipal Solid Waste, Wood, Tyres, Plastic, E-waste, Packing material, textile, Drum, Metals, oversize bulky waste, industrial waste, General Waste, Hazardous Waste, end of life equipment and other difficult to shred items. The heavy duty shredders are manufactured by us upto 10 tons/hr capacity.

Some of the highlighting features of our twin shaft shredder include:

Robust and rugged machines that have throughput up to 10 tons/hr

Safe to operate and very low vibration

Lower noise and dust which means a safe work environment

Lower power requirements and higher reliability

Lower risk and longer life of the equipment