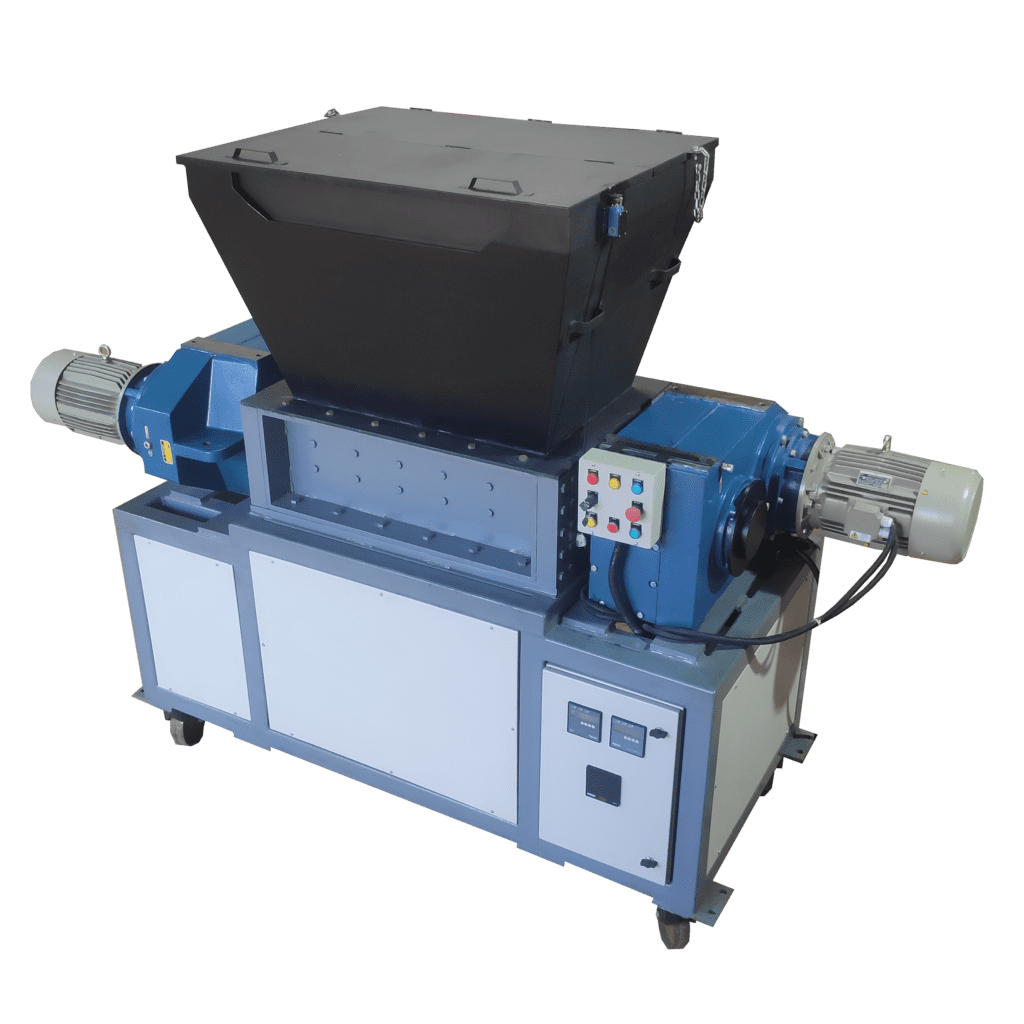

Rubber Shredder

Recycling rubber especially recycling scrap tires can provide crumb rubber for a variety of applications. During the whole rubber recycling process, the size reduction is the very important and necessary process. Rubber shredder and rubber granulator work together to produce big scrap rubber products into uniform cut and high quality granules. For some simple rubber products, a rubber granulator can work individually since it is the more efficient directly from rubber product to small granules.

Rubber granulator in rubber recycling

For rubber processing, rubber granulator is specialized designed for rubber granulating process. The end product after granulation process is much smaller than that from rubber shredding process. So it is typically the third station in the tire recycling line. After tire granulating process, the end product normally is fiber free and wire free rubber crumb. The first shredder and secondary shredder can shred tires into 20mm rubber for example. Then this granulator can grind them further into 5mm granules. Of course, the desired size can be adjustable because screens with different hole sizes available to ensure a more flexible production. The adjustable knifes optimize the cutting function. Also the exchangeable wear parts give a tough machine.

While there are a multitude of similarly designed granulators in the market, it is quite important to look for the right machine which is engineered especially for the type of material you want to process.

PROKATO Rubber Granulators

PROKATO has great experience in providing size reduction solutions for a broad range of materials and applications. Our rubber granulator feature with its performance, durability as well as reliability. For rubber crushing, please send PROKATO team your own size reduction requirements, we will provide you with a high performance machine which meets your precise size and production requirements.

Shredded Rubber can be so useful, you have no idea!

A rubber shredder plays a crucial role in the recycling of rubber by breaking down rubber materials into smaller pieces or shreds. Here’s how it helps in the recycling process:

Size Reduction

Rubber shredders are designed to reduce the size of rubber waste, such as tires, conveyor belts, or other rubber products. The PROKATO shredder uses powerful blades or rotating discs to cut the rubber into smaller, more manageable pieces. This size reduction step increases the surface area of the rubber, making it easier to process in subsequent stages.

Supports Various Recycling Methods

Rubber shredders are compatible with different recycling methods. Shredded rubber can be further processed through methods like cryogenic grinding, granulation, or devulcanization to obtain reusable rubber compounds or powders. The shredded rubber can also be used as a fuel source in waste-to-energy plants or as an additive in cement kilns.

Improves Material Handling

Our MADE-IN-INDIA Rubber shredders also help in the efficient handling of rubber waste. Shredded rubber occupies less space, making it easier to store, transport, and feed into other recycling equipment.

Enhances Processing Efficiency

Shredding rubber improves the efficiency of downstream processes. Shredded rubber has a larger exposed surface area, which allows for more effective mixing, blending, or grinding during subsequent recycling steps. For example, shredded rubber can be used as a raw material in the production of new rubber products, such as playground surfaces, athletic tracks, or rubberized asphalt.

Facilitates Sorting

After shredding, the rubber pieces can be sorted more effectively. Shredding helps to separate rubber from other materials like steel wires or fabric reinforcements present in tires. The smaller shredded rubber pieces can be further processed to remove these contaminants, enabling better recycling and recovery of the rubber material.

Overall, PKT Rubber Shredders aid in the recycling of rubber by reducing its size, facilitating sorting, improving processing efficiency, and enhancing material handling. By shredding rubber waste, valuable resources can be recovered, and the environmental impact associated with rubber disposal can be minimized.

Our PROKATO Industrial Shredding Machine is built to satisfy all your requirements!

Contact us on +919820020754 for more details.